INRAE Research on Sorghum Grain Digestibility

Hamza Mameri is in charge with INRAE (processing department) research and is part of the Soft Matter (I2M) Engineering team working within the Joint Research Unit of the IATE (centre for Agropolymer Engineering and Emerging Technologies). His employment by the JRU five years ago resulted in several multidisciplinary works focusing on improving the quality of sorghum grain protein digestibility, with a view to better harnessing the plant in human food and/or feed use.

Sorghum ID – What does your research on sorghum consist in?

Hamza Mameri – «With financial support from the GloFoods metaprogramme, from INRAE’s processing department and our team’s funds, we are developing several projects initiated by students whose PhD defence topics concern sorghum. The projects look into the relationship between the composition, structure, and characteristics of storage proteins, with a view to developing healthy, shelf-stable foods. One aspect which we are particularly interested in with regards to sorghum proteins is their digestibility.

For instance, we study the impact of primary processing (fractioning, germination, etc) on the nutritional characteristics of sorghum proteins.

Then we look at the secondary processing (the transformation of cereal flours into current consumer foods such as pastas, bread, couscous, and others). For example, we have a study on the impact of extrusion1 on phenolic compounds and the physical and chemical properties of proteins».

Sorghum ID – What does that mean, more specifically?

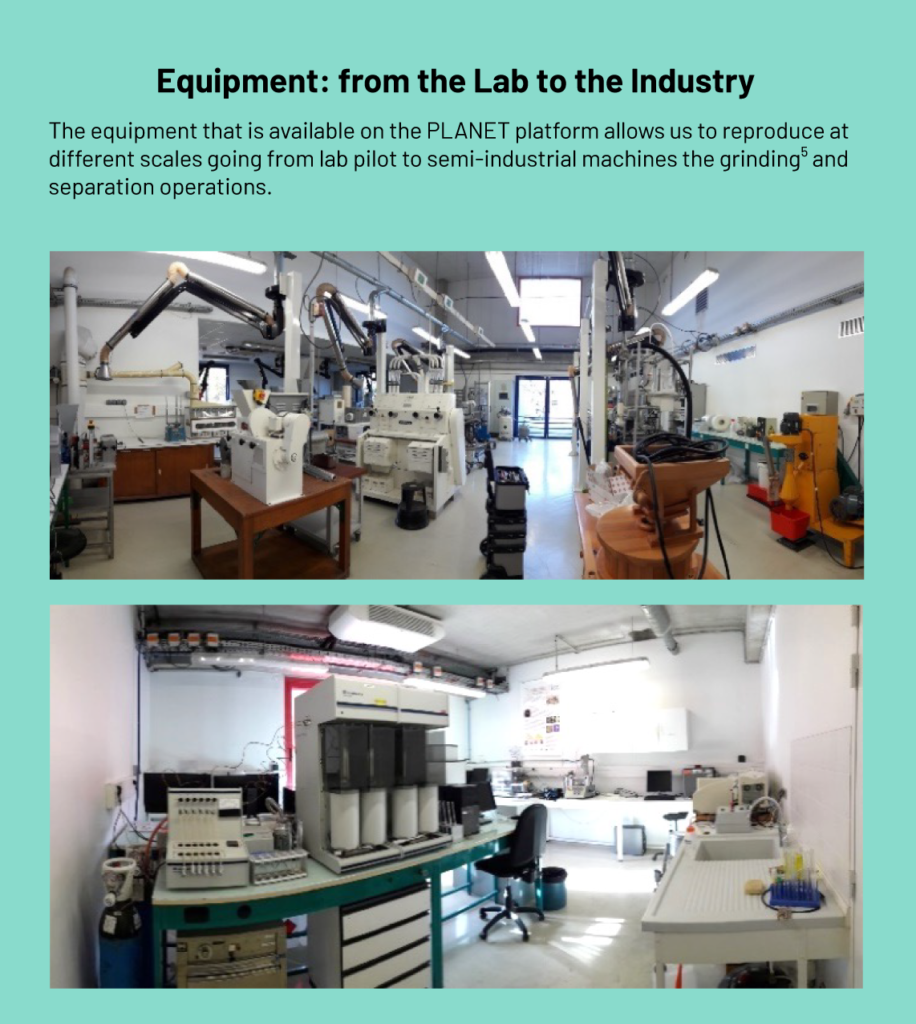

H.M. – «We start with a mature, harvested grain, which we hull, ground, and fraction to produce flour, semolina, or other by-products2. We observe the grain’s hulling closely: we make detailed descriptions of the resulting flours and their compositions (proteins, phenolic compounds, starch, fibre, etc), in order to optimize both the method and the yields. On our PLANET platform we have all the tools and equipment we need in order to study the processes of product development and structuring (mixing, hydration, extrusion, and drying during dough formation3, for example).

What we actually do is analyse the process at every step, using state-of-the-art tools, developed by, and available in, our laboratory. Lastly, we look at the effect that the boiling methods have on digestibility, by varying key parameters such as temperature.

For products issued from the primary or secondary processing, we draw structural and physical and chemical descriptions using spectroscopy methods (such as infrared spectroscopy), NMR4, chromatography, and light diffusion, among others. Then we test for hydrolysis capacity using enzymes from the digestive tract of monogastric species».

![]()

Sorghum ID – What is the structure of the Joint Research Unit (UMR) of the IATE ?

H.M. – «The JRU has three main research axes: food sciences and technologies; biotechnology and biorefinery; modelling and simulation.

These three different areas are covered by eight research teams, which include the Soft Matter (I2M) Engineering team (I2M), and a support platform, called PLANET (Platform for Processing of Plant Products using Emerging Technologies), focusing on plant processing and harnessing. The platform provides JRU researchers with specialised equipment and personnel to assist them with implementing their research projects.

My I2M team studies plant proteins, more specifically – especially storage proteins of grain crops (wheat and sorghum), in order to learn about the effect that processing methods have on their characteristics, including digestibility.

We work with in-house partners, whether IATE or INRAE, as well as with external partners, be they public or private – such as CIRAD and other (international) bodies. We currently work with university laboratories in Brazil and Canada, studying the impact that kernel processing methods have on phenolic compounds and protein digestibility.

Sorghum ID – How do you share the results of your work?

H.M. – «Our results are solid enough to be shared with the professional community. We do this through scientific publications, but we will also share a number of our activities during the main 2023 meetings, especially at the World Sorghum Congress, which will be held in June, in Montpellier».

Be sure not to miss the upcoming 2023 meetings on food markets!

- The 14th European edition of the Sustainable Foods Summit – June 15-16, 2023, Amsterdam, the Netherlands.

- World Sorghum Conference – June 5-9, 2023, Montpellier.

Learn more

1. Extrusion in food processing consists in forcing a mixture of ingredients through an opening in a perforated plate or die designed to produce the required shape. The extruded food is then cut to a specific size by blades.

2. . A by-product is a product derived from the same manufacturing process and at the same time with the main product.

3. The dough-making process transforms hard wheat semolina into food pasta, through a kneading operation and an extrusion operation, using specific shaping tools.

4. NMR: nuclear magnetic resonance.

5. Grinding: a milling operation which consists in reducing grain kernels into flour.

Continue ?

International Agricultural Show – 2023:

Full House for Sorghum

Multiuse